Description

SKU # 10-205F , 36983

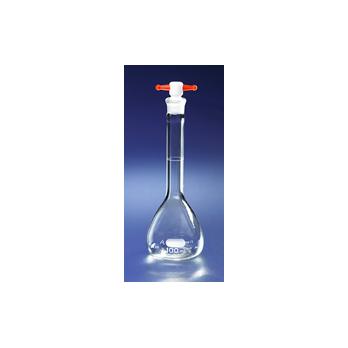

Class A, USP, certified volumetric flasks. These are supplied with a glass stopper with a dripping tip. Available in both transparent and amber color. High contrast blue enamel print on transparent flasks, and white on amber flasks, represent the optimum combination of resistance and readability. Available in all ISO sizes from 5mL to 2000mL. Made of low expansion coefficient, chemically resistant borosilicate 3.3. Volumetric flasks are indispensable for preparing dilutions and standard solutions. All BLAUBRAND® USP volumetric flasks are supplied with a batch number and an accompanying USP batch certificate in the original packaging.

Volumetric instruments according to USP error limits

Companies producing pharmaceutical products for the US market are supervised by US authorities, e.g. the FDA (Food and Drug Administration), and have to meet the requirements of the USP (United States Pharmacopeia). The current USP prescribes in section 31 the use of volumetric instruments with accuracy in accordance to class A of the ASTM standards and list those for volumetric flasks, transfer pipettes and burettes in tables. For graduated pipettes up to and including 10 mL size the error limits are mentioned in the text. BRAND volumetric instruments are manufactured according to the current DIN EN ISO standards. As the construction specifications are differently defined in the DIN EN ISO and ASTM standards, the error limits differ as well. With included USP certificates BRAND confirms for the delivered USP volumetric instruments that the class A error limits according to the USP or, rather, ASTM standards are met.

Every glass volumetric measuring instrument is individually calibrated. Computer-controlled systems ensure maximum precision in a fully automated production line. The final step of this Statistical Process Control is random sampling of finished product according to DIN ISO 3951. The quality management system applied at BRAND, which is certified according to DIN EN ISO 9001, is a combination of process monitoring and random checks with an accepted quality level (AQL) of approximately 0.4.

The batch certificate confirms that ASTM class A error limits required by USP are met. The certificate records the mean value, the standard deviation of the batch and the date of issue (batch number: year of manufacture/batch).